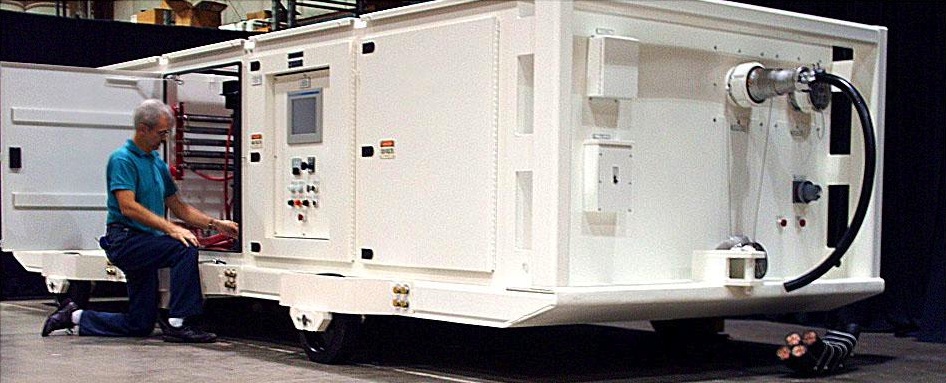

End View

|

Front View

|

Imput Line Reactor

|

Liquid Cooled Rectifier and Inverter

|

Liquid Cooling Controls

|

Low Voltage Controls

|

|

4160 Volt VFD Underground Motor Controller

- Liquid Cooled Components

- Active Front End - No Transformer

- 3300 - 6900 VAC

- 700 - 2500 HP

- Skid-Mounted Continuous Weld Design

- Input and Output Couplers Standard

- Rubber Tire Option

- Voltages from 3300 to 6900 AC

- Horsepowers from 750 to 2500

- Regenerative Applications Standard

- Constant Torque Duty - 150% Overload Standard

- Custom Design Allows for 250% Overload

PowerFlex 7000 Kit

Rockwell Automation PowerFlex 7000 Liquid-Cooled Direct-to-Drive kit packaged for Underground Use

- Active Front End (AFE) is Regenerative - Standard

- AFE means no Integral Transformer Required

- Direct-to-Drive (D2D) means 4160 vac In and 4160 vac Out to Motor

- Liquid Cooled Components Stay Cooler and Cleaner = Longer Life

- Reduces Harmonics on Electrical Systems

Liquid Cooling for Longer Life!

- Closed-Loop De-Ionizing Liquid Cooling

- Integral Flat Plate Heat Exchanger Keeps Closed-Loop System Clean and Contained

- Flange Fittings for Mine Cooling Water Input and Hot Water Return

- Redundant Pumps for Ease of Maintenance

- Controls Monitor Temperature, Pressure, and Conductivity of Cooling Liquid

Underground Mining Equipment VFD Motor Controls

- Face Conveyor and Stageloader Applications

- Torque and Speed Control

- Enhanced Overload Capacity

Allows Face Conveyor to Operate at Reduced Speeds:

- Minimizes Chain Wear by up to 40%

- Reduces Energy Costs

- Extends Time Between Rebuilds

Extreme Overload Capabilities:

- PowerFlex 7000 Kit May be Customized

- Normal Duty at 110%, Heavy Duty at 150%

- Mine Duty at 280% Overload for 20 seconds of Each 120 Seconds

- 6.6 kv Rectifiers with Oversized DC Link Choke and Input Line Reactor

Modular Liquid Cooled Design:

- Used in Multiple Motor Configurations, Add or Remove Motors as Required

- Separate Controls in Skid or Wall Mounted Configuration

- Closed Loop Liquid Cooling System Keeps VFD Cooler and Cleaner for Increased Life and Reliability

- Motor Leads Up to 10 KM

4160 Volt VFD for Underground Belt Conveyor Controls

- Modular Design Provides Flexibility in Number of Motors Used

- Main or Booster Applications

- Torque and Speed Control

Unlimited Conveyor Start Time Minimizes Belt Tensions:

- Minimizes HP Required and Conveyor Component Sizes

- Reduces TakeUp Requirements

- Extends Belt Life

Allows Conveyor to Operate at Reduced Speeds:

- When Less Than Design TPH is Required Conveyor Speed May Be Reduced Belt Inspection Speed for Maintenance

Modular Liquid Cooled Design:

- Used in Multiple Motor Configurations, Add or Remove Motors as Required

- Separate Belt Controls in Skid or Wall Mounted Configuration

- Closed Loop Liquid Cooling System Keeps VFD Cooler and Cleaner for Increased Life and Reliability

Lower Electrical Harmonics:

- Active Front End Provides Regenerative Ability

- Active Front End Meets IEEE-519 Requirements

- SGCT Devices Use Slower Switching Frequencies Reducing Common Mode Noise

- Eliminates Need for Drive Isolation Transformers

- Eliminates Harmonics Damage to Electrical Distribution Equipment

- Motor Lead Lengths Up to 10 KM

Reduces Installation Cost of Low Voltage:

- Saves on Cable Cost

- Smaller Cables Reduce Installation Time

- For 400' of Cabling:

Saves Over $70,000 in Cable Cost

Requires Less Than 1/3 of Time to Install or Move

|